8 5 Predetermined Overhead Rates & Overhead Application Financial and Managerial Accounting

The predetermined overhead rate8 is calculated prior to the year in which it is used in allocating manufacturing overhead costs to jobs. The activity used to allocate manufacturing overhead costs to jobs is called an allocation base7 . Thus each job will be assigned $30 in overhead costs for every direct labor hour charged to the job. The assignment of overhead costs to jobs based on a predetermined overhead rate is called overhead applied9. Remember that overhead applied does not represent actual overhead costs incurred by the job—nor does it represent direct labor or direct material costs. Instead, predetermined overhead rate overhead applied represents a portion of estimated overhead costs that is assigned to a particular job.

Is rent an overhead cost?

At this point, do not be concerned about the accuracy of the future financial statements that will be created using these estimated overhead allocation rates. That amount is added to the cost of the job, and the amount in the manufacturing overhead account is reduced by the same amount. At the end of the year, the amount of overhead estimated and applied should be close, although it is rare for the Bookkeeping for Consultants applied amount to exactly equal the actual overhead. For example, Figure 8.41 shows the monthly costs, the annual actual cost, and the estimated overhead for Dinosaur Vinyl for the year. Another tremendous advantage for companies using the predetermined overhead rate is it provides a more consistent analysis even during periods of season variability.

- Cost objects are items for which costs are compiled, such as products, product lines, customers, retail stores, and distribution channels.

- The overhead is then applied to the cost of the product from the manufacturing overhead account.

- Overhead expenses include accounting fees, advertising, insurance, interest, legal fees, labor burden, rent, repairs, supplies, taxes, telephone bills, travel expenditures, and utilities.

- Using a predetermined rate, companies can assign overhead costs to production when they assign direct materials and direct labor costs.

- Establishing the overhead allocation rate first requires management to identify which expenses they consider manufacturing overhead and then to estimate the manufacturing overhead for the next year.

- The overhead used in the allocation is an estimate due to the timing considerations already discussed.

- Once the allocation base is selected, a predetermined overhead rate can be established.

Is fuel an overhead cost?

Overhead expenses are items that are required to sell products and run the company in general. The cost of these items is not dependent upon the total number of units produced by the company. In other words, a company’s rent will not change if they produce 1000 units in a reporting period or if they don’t produce any units. Most companies will adopt the use of predetermined overhead rates in order to know how their products are performing even before the accounting period ends. It is a way to constantly evaluate the profitability of manufacturing instead of waiting until that reporting period comes to an end. Applied overhead is the amount of overhead cost that has been applied to a cost object.

Determining Estimated Overhead Cost

- Estimating overhead costs is difficult because many costs fluctuate significantly from when the overhead allocation rate is established to when its actual application occurs during the production process.

- The predetermined overhead rate takes these variations into consideration and offers a more dependable estimated overhead total.

- When companies begin the planning process of manufacturing a product, cost projections are a large and important focus.

- The process of creating this estimate requires the calculation of a predetermined rate.

- Added to these issues is the nature of establishing an overhead rate, which is often completed months before being applied to specific jobs.

Another way to view it is overhead costs are those production costs that are not categorized as direct materials or direct labor. To gain a better understanding of this concept, it is important to understand the differences between operating expenses and overhead expenses. In general, management teams will divide expenses between these two categories because unearned revenue they provide broader insight into an accurate product cost and the manufacturing of a product. As more and more products are produced, the greater the effect on profitability.

Does overhead include salaries?

- The rate is configured by dividing the assumed overhead amount for a particular period by a certain activity base.

- Boeing provides products and services to customers in 150 countries and employs 165,000 people throughout the world.

- The application rate that will be used in a coming period, such as the next year, is often estimated months before the actual overhead costs are experienced.

- •A company usually does not incur overheadcosts uniformly throughout the year.

Office supplies are considered overhead because they do not directly create revenues. Electricity is a cost that can vary from month to month and is a variable overhead cost unless it is part of the production process. To calculate the overhead rate, divide the total overhead costs of the business in a month by its monthly sales. For example, say your business had $10,000 in overhead costs in a month and $50,000 in sales.

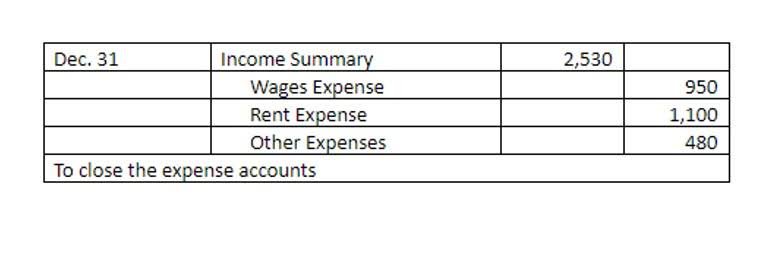

Alternative Approach to Closing the Manufacturing Overhead Account

- •Predetermined rates make it possible for companies to estimate job costs sooner.

- Boeing Company is the world’s leading aerospace company and the largest manufacturer of commercial jetliners and military aircraft combined.

- Most companies will adopt the use of predetermined overhead rates in order to know how their products are performing even before the accounting period ends.

- Specifically, the predetermined overhead rate is an approximated ratio of manufacturing overhead costs determined in advance based on variable and fixed costs.

- You can envision the potential problems in creating an overhead allocation rate within these circumstances.

The goal is to allocate manufacturing overhead costs to jobs based on some common activity, such as direct labor hours, machine hours, or direct labor costs. The activity used to allocate manufacturing overhead costs to jobs is called an allocation base7. Once the allocation base is selected, a predetermined overhead rate can be established.